The Artistry of Tai Ping

The complexity of Tai Ping creations calls for exceptional artisanal skills. The standard of excellence that has defined the Tai Ping brand since 1956 is evidence not only in the company’s exquisitely handcrafted products but also in the spirit and commitment of its workers at all levels of design and execution.

On a daily basis, Tai Ping artisans transform the most complicated custom designs into works of art that exceed the expectations of discerning customers worldwide. Tai Ping’s ethos of community, longevity and employee care began in the company’s first workshop in 1956 and it proudly continues today.

Design

A Tai Ping custom project typically starts with design development. The client may propose their own ideas, or may use a Tai Ping collection, or they may simply have a colour palette and genre in mind and leave the rest to the Tai Ping design team. Tai Ping offers 80+ different material choices, including wool, silk, cashmere, flax and cotton. The standard pom box contains 560 colour choices, although each year over 2,000 unique colours are produced.

Sampling

During the design development process, custom handmade samples are generally prepared for the client’s review and approval, based on which, the order is placed. Tai Ping typically produces 3,000-4,000 samples per month.

Samples offer clients the opportunity to see and feel the precise aesthetic of the custom product they are creating. Texture, density, softness and colours are among the many traits that can be experienced through the sampling process.

Template Production

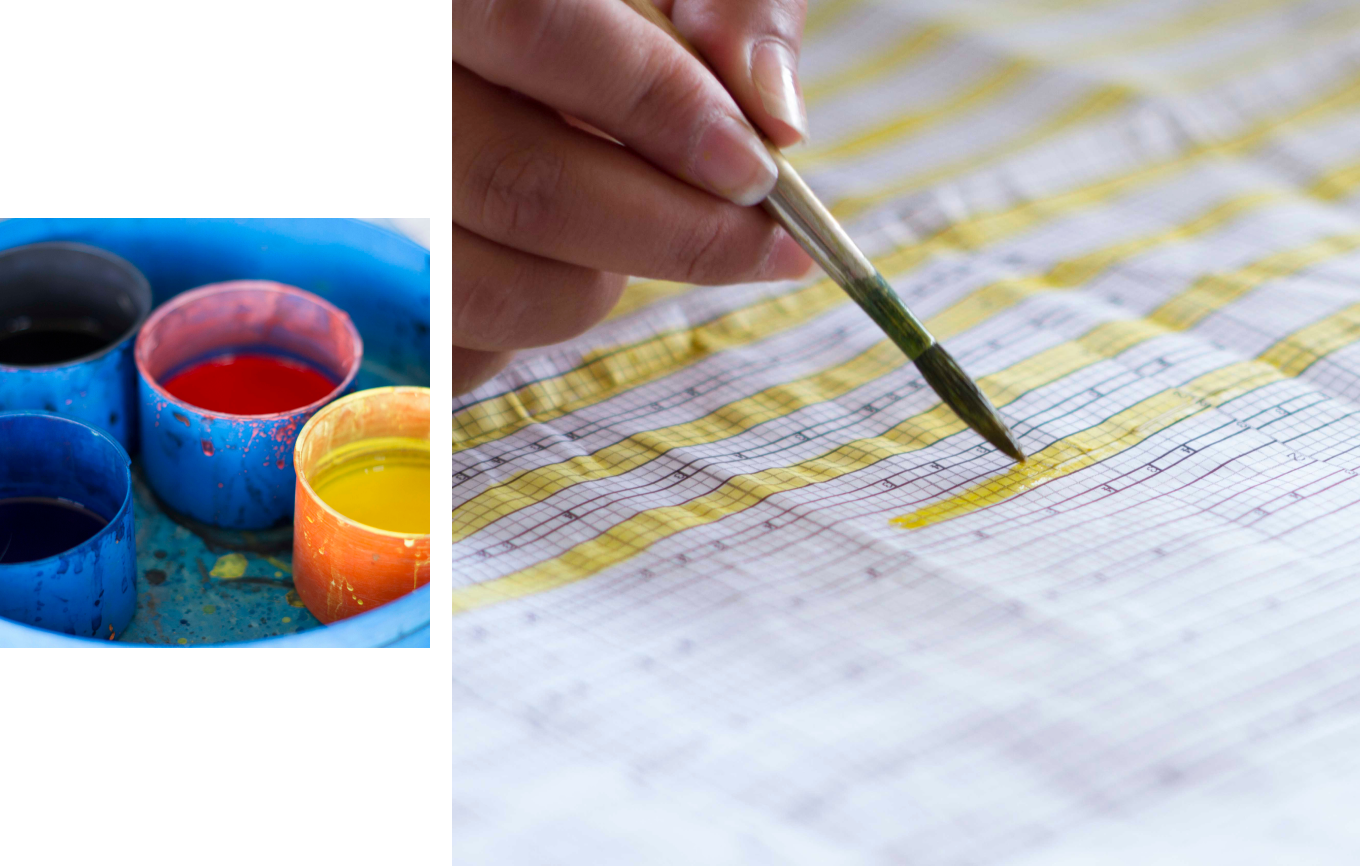

The first step in the production of a Tai Ping carpet is to enlarge the design to actual size and create a full-size template. The design is mapped onto large acetate sheets by laser plotting, with the design outline traced as a line of tiny perforations.

Once the template is prepared, it is attached to a large vertically stretched canvas, and the pattern outline is transferred to the canvas by brushing ink onto the acetate, which seeps through the holes. Then an artist finishes the pattern on the canvas by hand.

Dyeing

Dyeing is a critical process and among the most demanding challenges faced by TaiPing: discerning design-oriented clients require precision colour-matching … not made easier by the fact that people see colour differently! The recipe for any new colour is developed using a computer-controlled recipe formulations machine. This calculates the types, quantities and combination of dyestuffs to deliver the required colour. Then it prepares the recipe, which is scaled up to produce the production batch in the dye house. All completed yarn batches are also visually assessed by skilled colourists, using four different types of light – daylight, fluorescent, UV and infrared.

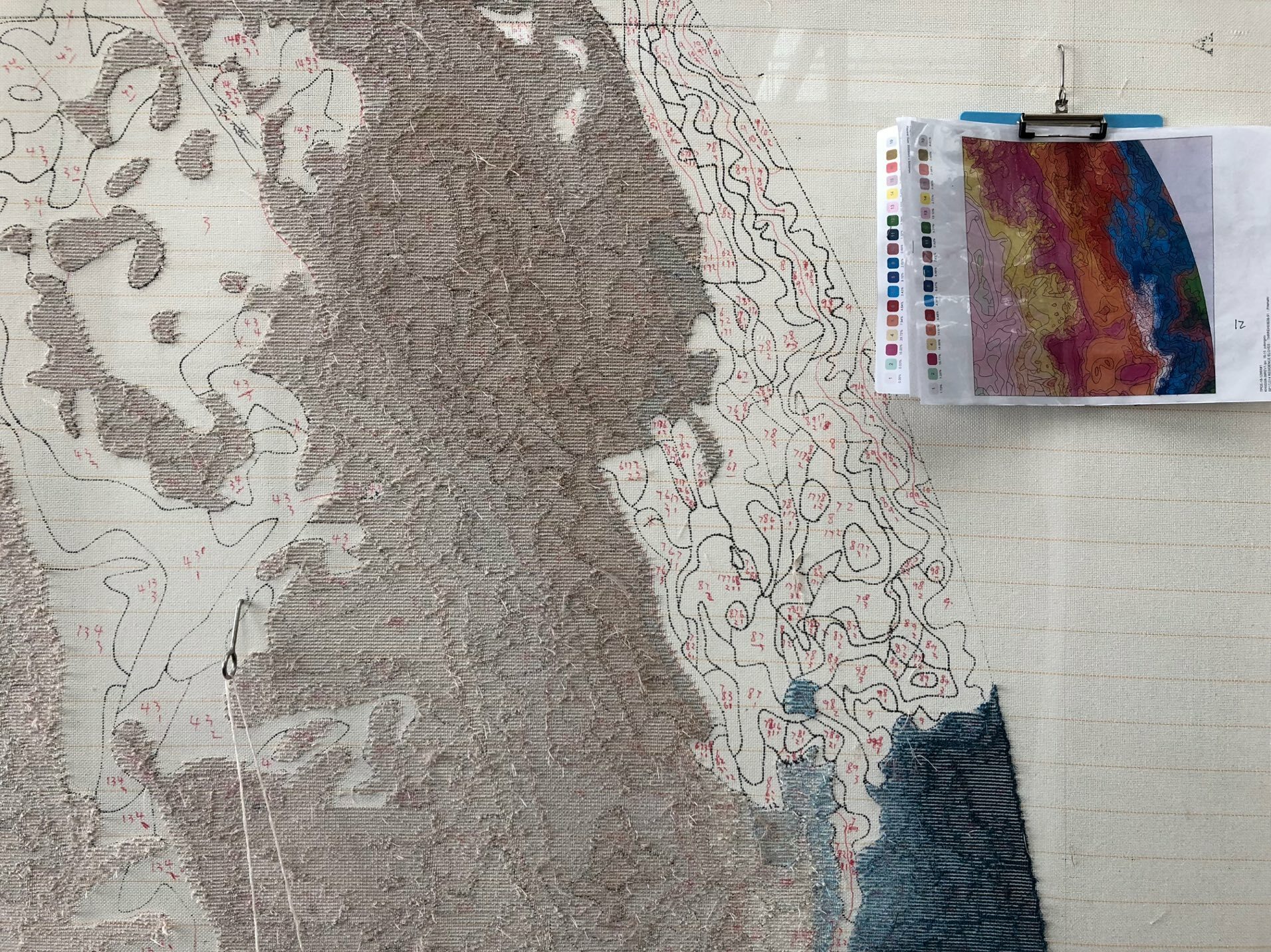

Tufting

Once the inked canvas and dyed yarn preparation stages are complete, the carpet is created by skilled artisans with many years of training in the hand-tufting process. The canvas is stretched vertically, and the artisans use special hand-tufting guns designed by Tai Ping to apply the yarns to the canvas, with each colour applied individually in turn.

While the design outlines on the canvas provide an overall guide, the artisan relies on experience and carefully-structured training to ensure the correct pile height, direction, cut or loop. In addition, many fine details depend on the artisan’s hand-to-eye coordination and artistic interpretation. The more complex designs require immense skill, with only a small proportion of the tufters qualified to perform this work.

Finishing

Artisans on the finishing floor start by finely hand-shearing the carpet’s surface to give it smooth, consistent finish. Many orders feature a complex texture with varying pile heights along with special carving, sculpting or embossing effects.

The most skilled finishing artisans, with years of experience, perform these intricate operations with hand shears and scissors. A final inspection takes place to verify the dimensions, design execution, aesthetic and all technical parameters such as weight and pile height.